STUDY OF SOME PHYSICAL PROPERTIES OF BRIQUETTES FROM DIFFERENT FOREST WOODY BIOMASS COLLECTIONS IN KURDISTAN REGION OF IRAQ

Abstract

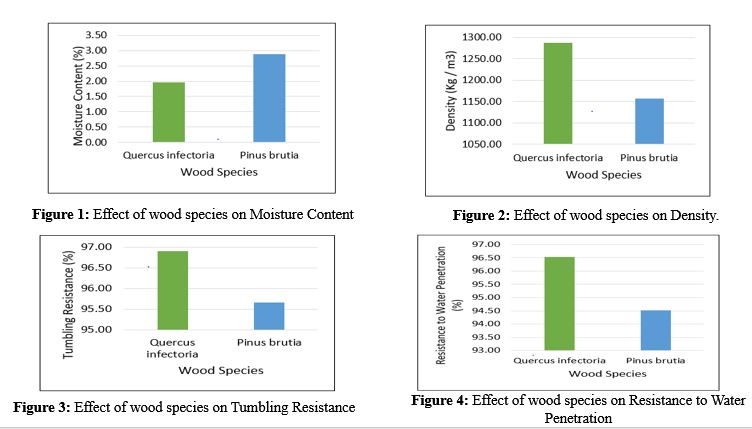

By using forest waste, energy sustainability can be improved, and biomass briquettes offer a sustainable and eco-friendly substitute for fossil fuels. This study examines the physical characteristics of briquettes made from various woody biomass species, as a result of assessing factors including the amount of moisture, density, shatter resistance, tumble resistance, and resistance to water penetration. Also, to identify ideal production circumstances, in both tree species (Quercus infectoria and Pinus brutia). Factors were particle size (2 and 4 mm), moisture levels (6, 9, and 12%), and briquetting temperature (330 and 350 °C). According to the results, Quercus infectoria briquettes processed at 350 °C, with particle sizes of 2 mm and moisture levels of 6%, showed enhanced physical characteristics and combustion efficiency. Longer burning times were caused by higher compactness, and storage stability was improved by resistance to water penetration. These results offer insightful information for the biofuel sector, assisting producers in improving their methods of production to produce premium, environmentally friendly biomass briquettes. The study advances the larger objective of lowering reliance on energy sources that are not renewable and advancing sustainable energy solutions by enhancing the durability and efficiency of biomass fuels. The findings support more investigation into improving biomass briquetting procedures for increasing environmental and financial advantages

Full text article

References

Ahmad, M., Rajapaksha, A. U., Lim, J. E., Zhang, M., Bolan, N., Mohan, D., ... & Ok, Y. S. (2014). Biochar as a sorbent for contaminant management in soil and water: a review. Chemosphere, 99, 19-33. https://doi.org/10.1016/j.chemosphere.2013.10.071

Antal, M. J., & Grønli, M. (2003). The Art, Science, and Technology of Charcoal Production. Industrial & Engineering Chemistry Research, 42(8), 1619-1640. https://doi.org/10.1021/ie0207919

Arias, B., Pevida, C., Fermoso, J., Plaza, M. G., Rubiera, F., & Pis, J. J. (2008). Influence of torrefaction on the grindability and reactivity of woody biomass. Fuel processing technology, 89(2), 169-175. https://doi.org/10.1016/j.fuproc.2007.09.002

ASTM International. (2003). ASTM D3173-03: Standard Test Method for Moisture in the Analysis Sample of Coal and Coke. West Conshohocken, PA: ASTM International. https://doi.org/10.1520/D3173-03

Babu, B. V. (2008). "Biomass pyrolysis: A state-of-the-art review." Biofuels, Bioproducts and Biorefining, 2(2), 101-117. https://doi.org/10.1002/bbb.65

Bhattacharya, S. C., & Sarker, S. C. (1999). Physical Properties and Quality of Briquettes Made from Biomass and Charcoal. Renewable Energy, 7(2), 219-228. https://doi.org/10.1016/S0960-1481(97)10032-5

Birwatkar, V. R., Khandetod Y. P, Mohod A. G, and Dhande K. G.(2014). PHYSICAL AND THERMAL PROPERTIES OF BIOMASS BRIQUETTED FUEL, Ind. J. Sci. Res. and Tech. 2(4),pp:55-62. https://doi.org/10.17485/ijst/2014/v2i4.12

Bowyer, J. L., Shmulsky, R., & Haygreen, J. G. (2007). Forest Products and Wood Science: An Introduction (5th ed.). Blackwell Publishing. https://doi.org/10.1002/9780470756379

Bridgwater, A. V. (2012). "Review of fast pyrolysis of biomass and product upgrading." Biomass and Bioenergy, 38, 68-94. https://doi.org/10.1016/j.biombioe.2011.01.048

Carrier, M., Loppinet-Serani, A., Denux, D., Lasnier, J. M., Ham-Pichavant, F., Cansell, F., & Aymonier, C. (2011). Thermogravimetric Analysis as a New Methodology for Determining the Lignocellulosic Composition of Biomass. Biomass and Bioenergy, 35(1), 298-307. https://doi.org/10.1016/j.biombioe.2010.08.067

Demirbas, A. (2001). Biomass resource facilities and biomass conversion processing for fuels and chemicals. Energy Conversion and Management, 42(11), 1357-1378. https://doi.org/10.1016/S0196-8904(00)00137-0

Demirbas, A. (2004). "Effects of temperature and particle size on biochar yield from biomass." Energy Sources, 26(4), 331-340. https://doi.org/10.1080/00908310490429728

Downie, A., Crosky, A., & Munroe, P. (2009). Physical Properties of Biochar. In J. Lehmann & S. Joseph (Eds.), Biochar for Environmental Management: Science and Technology (pp. 13-32). Earthscan. https://doi.org/10.4324/9781849770552

Forest Products Laboratory. (2010). Wood Handbook: Wood as an Engineering Material. USDA. https://doi.org/10.2737/FPL-GTR-190

Garcia, R., Pizarro, C., Lavin, A. G., & Bueno, J. L. (2014). Biomass proximate analysis: Interpretation and comparison of data. Renewable and Sustainable Energy Reviews, 36, 158-165. https://doi.org/10.1016/j.rser.2014.04.081

Gil, M. V., Oulego, P., Casal, M. D., Pevida, C., Pis, J. J., & Rubiera, F. (2010). Mechanical Durability and Decomposition of Biomass Pellets During Long Term Storage. Bioresource Technology, 101(3), 939-947. https://doi.org/10.1016/j.biortech.2010.06.062

Grover, P. D., & Mishra, S. K. (1996). Biomass briquetting: Technology and practices. Food and Agriculture Organization of the United Nations. https://www.fao.org/4/AD579E/AD579E00.htm?utm_source=chatgpt.com

Ismail, S. M., & Ahmed, S. M. (2023). The effect of calcination temperatures on the properties of ZnO nanoparticles synthesized by using leaves extracts of pinus brutia tree. Science Journal of University of Zakho, 11(2), 286-297. https://doi.org/10.25271/sjuoz.2023.11.2.1087

Kaliyan, N., & Morey, R. V. (2009). Densification characteristics of corn stover and switchgrass. Biomass and Bioenergy, 33(8), 1145-1150. https://doi.org/10.1016/j.biombioe.2009.05.004

Khalil, H. P. S. A., & Sulaiman, F. (2012). Physical and thermal properties of biomass briquettes from oil palm and rice husk. Bioresource Technology, 109, 295-300. https://doi.org/10.1016/j.biortech.2011.10.030

Liu, Z., Quek, A., Hoekman, S. K., & Balasubramanian, R. (2013). Production of Solid Biochar Fuel from Waste Biomass by Hydrothermal Carbonization. Fuel, 103, 943-949. https://doi.org/10.1016/j.fuel.2012.08.056

Lua, A. C., Yang, T., & Guo, J. (2004). "Effects of pyrolysis conditions on the properties of activated carbons prepared from pistachio-nut shells." Journal of Analytical and Applied Pyrolysis, 72(2), 279-287. https://doi.org/10.1016/j.jaap.2004.08.001

Madhava M, Prasad BV, Koushik Y, Rameshbabu KR & Srihari R (2012). Performance evaluation of a hand operated compression type briquetting machine. Journal of Agricultural Engineering, 49(2) 46-49. https://ebook.icar.gov.in/index.php/JAE/article/view/24263

Mani, S., Tabil, L. G., & Sokhansanj, S. (2006). Effects of compressive force, particle size and moisture content on mechanical properties of biomass pellets. Biomass and Bioenergy, 30(7), 648-654. https://doi.org/10.1016/j.biombioe.2005.01.004

Mohan, D., Sarswat, A., Ok, Y. S., & Pittman, C. U. (2014). "Organic and inorganic contaminants removal from water with biochar, a renewable material: A critical review." Bioresource Technology, 160, 191-202. https://doi.org/10.1016/j.biortech.2014.01.120

Pelaez-Samaniego, M. R., Smith, A. R., Kashaninejad, N., & Steele, P. H. (2014). Mechanical Properties of Biochar Pellets. Biomass and Bioenergy, 62, 1-7. https://doi.org/10.1016/j.biombioe.2014.01.024

Pérez, J. M., Melgar, M., Benjumea, P., & Ramos, C. (2019). Effect of particle size on bio-briquettes properties. Fuel, 256, 115924. https://doi.org/10.1016/j.fuel.2019.115924

Prins, M. J., Ptasinski, K. J., & Janssen, F. J. (2006). "More efficient biomass gasification via torrefaction." Energy, 31(15), 3458–3470. https://doi.org/10.1016/j.energy.2006.03.008

Ronsse, F., Van Hecke, S., Dickinson, D., & Prins, W. (2013). Production and Characterization of Slow Pyrolysis Biochar: Influence of Feedstock Type and Pyrolysis Conditions. Biomass and Bioenergy, 48, 43-54. https://doi.org/10.1016/j.biombioe.2012.10.007

Schellenberger, S., Schmiedl, D., & Kruse, A. (2019). "Thermal degradation of wood particles: Influence of size and temperature." Journal of Analytical and Applied Pyrolysis, 137, 166-174. https://doi.org/10.1016/j.jaap.2018.11.017

Shahbaz, S. E., Abdulrahman, S. S., & Abdulrahman, H. A. (2015). Use of Leaf Anatomy for Identification of Quercus L. Species Native to Kurdistan-Iraq. Science Journal of University of Zakho, 3(2), 222-232. https://sjuoz.uoz.edu.krd/index.php/sjuoz/article/view/146?utm_source=chatgpt.com

Shen, D. K., Gu, S., Luo, K. H., Wang, S. R., & Fang, M. X. (2009). "The pyrolytic degradation of wood-derived lignin from pulping process." Bioresource Technology, 100(3), 649–655. https://doi.org/10.1016/j.biortech.2008.07.033

Siau, J. F. (1984). Transport Processes in Wood. Springer. https://doi.org/10.1007/978-3-642-69213-0

Sohi, S. P., Krull, E., Lopez-Capel, E., & Bol, R. (2010). "A review of biochar and its use and function in soil." Advances in Agronomy, 105, 47-82. https://doi.org/10.1016/S0065-2113(10)05002-9

Sokhansanj, S., Mani, S., Bi, X., et al. (2005). Binderless pelletization of biomass. ASABE Annual Meeting Paper. https://doi.org/10.13031/2013.19922

Tumuluru, J. S., Wright, C. T., Hess, J. R., & Kenney, K. L. (2011). A review of biomass densification systems to develop uniform feedstock commodities for bioenergy applications. Biofuels, Bioproducts and Biorefining, 5(6), 683-707. https://doi.org/10.1002/bbb.324

White, R. H., & Dietenberger, M. A. (2010). Wood Handbook: Wood as an Engineering Material. USDA Forest Service. https://doi.org/10.2737/FPL-GTR-190

Authors

Copyright (c) 2025 Dilgash Fayeq Yaseen, Aree Adel Abdulqader, Ahmed Saieed Abdulla

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors who publish with this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License [CC BY-NC-SA 4.0] that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work, with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online.